How To Remove 3m Dual Lock Adhesive

3M™ Dual Lock™ Introduction & Buying Guide

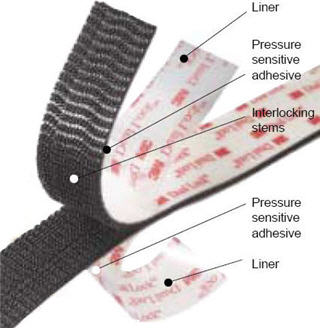

The Fastener

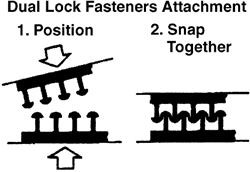

When two sides of 3M™ Dual Lock™ are pressed together, hundreds of mushroom-shaped stems interlock. "Snap" announces that the fastener is engaged. Compared to Claw & Loop the tensile strength is greater with 5x more holding ability

Guild your 3M™ Dual Lock™

Stalk Count/Types

There are three basic types/stem counts of standard 3M™ Dual Lock™ with and without adhesive.

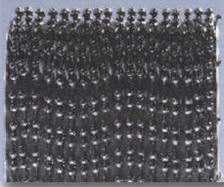

Type 250—Stems in Wave pattern, approximately 250 stems per inch.

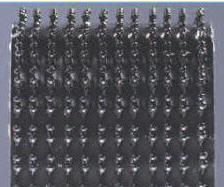

Type 170—wide rows, approximately 170 stems per inch.

Type 400—heads almost touching, approximately 400 stems per inch.

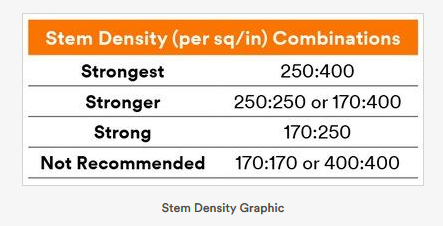

3M™ Dual Lock™ Stalk Count/Mating Chart

170 to 250

Easy opening for multiple closures. Low engagement force, low tensile strength.

250 to 250 or 170 to 400

Most Mutual: Medium engagement force balanced with moderate tensile strength.

250 to 400

Higher engagement strength counterbalanced with loftier tensile force.

Dual Lock to Loop fastener

Quick take hold of engagement, high peel force, very short cycle life

Adhesive Guide

| SJ3540SJ3541SJ3542 | SJ3550CFSJ3551CF | SJ3560SJ3561SJ3562 | SJ4570SJ4575 | SJ4580 | SJ3870SJ3871 | |

|---|---|---|---|---|---|---|

| Bare Metals | X | X | Ten | X | X | X |

| Painted Metals | X | X | X | X | X | |

| Fiberglass | Ten | 10 | X | X | X | |

| Structural Composites | Ten | X | X | 10 | ||

| Glass | X | Ten | 10 | Ten | X | |

| Sealed Woods | X | X | X | X | Ten | Ten |

| Powdered Coated Paints | X | 10 | X | |||

| ABS | X | X | X | X | X | X |

| Acrylic | X | X | 10 | Ten | X | X |

| Polycarbonate | X | X | Ten | X | X | X |

| Rigid Vinyl | X | X | X | Ten | 10 | X |

| Plasticized Vinyl | X | Ten | ||||

| Polyethylene | X | Ten | X (Primer Required) | |||

| Polypropylene | X | X | X (Primer Required) | |||

| Polystyrene | X | X | X | |||

| CARC Pigment | 10 | |||||

| Alkyd Enamel Pigment | X | |||||

| Painted Wood | X | X |

*SJ3872special social club

3M™ Dual Lock™ ID Guide

Store By the Chiliad, Trial Bags,Pre-cut Coins, Pre-cut Strips, EZpass Price Strips, or y'all can email your product numbers, dimensions and quantity for pricing on cut to length or cutting to shape parts to sales@iTapeStore.com. Retrieve, quantity discounts show in cart, run across our free ground shipping offer and New Jersey addresses will exist charged sales tax.

Store SJ3550CF, SJ3551CF

- Pictured SJ3550 white VHB acrylic adhesive (3M supply disruption, see CF, SJ3560, SJ3870, TB3550)

- SJ3550CF, SJ3551CF - Clear, UV resistant, acrylic adhesive

- Clear liner with carmine impress

- Blackness stems

- Stalk Count Guide/ID

Shop SJ3560, SJ3561, SJ3562

- Articulate liner with red print

- Clear, UV resistant, acrylic adhesive

- Articulate stems

- Stalk Count Guide/ID

Shop SJ3870, SJ3871, SJ3572

- Scarlet liner

- Black modified acrylic adhesive

- Black stems

- SJ3872 special society

- Stalk Count Guide/ID

Depression Profile:

Shop SJ4570

- Brown liner with green impress

- Clear acrylic adhesive

- Clear stems

- 705 stems per inch

Store SJ4575

- Dark-brown liner with green impress

- Clear acrylic agglutinative

- Black stems

- 705 stems per inch

Store SJ4580

- Red liner

- Clear LSE acrylic adhesive

- Clear stems

- 705 stems per inch

Shop NO Adhesive

Shop SJ3440 Blazon 250, SJ3441 Blazon 400, SJ3442 Type 170

- No adhesive

- Black stems

- Stem Count Guide/ID

Store SJ3460 Type 250

- No adhesive

- Clear stems

- Stem Count Guide/ID

The following information is intended to assist the designer because the utilize of 3M™ Dual Lock™ Reclosable Fasteners. Final product performance depends on actual atmospheric condition, including the fastener selected, the conditions in which the fastener is practical, the time and ecology weather condition in which information technology is expected to perform. Considering many of these factors are uniquely within the user'southward knowledge and control, information technology is required that the user evaluate the 3M™ production to make up one's mind whether it is fit for a particular purpose and suitable for the user'south method of application and desired cease employ.

Equally a full general rule, four foursquare inches of fastener area per pound of static load to exist supported is suggested every bit a starting point for evaluation. More or less area may be needed depending on specific conditions or stop use applications.

Pressure Sensitive Adhesive attachment: The fasteners and substrate surfaces should have equilibrated for a minimum of one 60 minutes at temperatures of 68F (20C) or greater earlier application. By and large these adhesive backed fasteners should be applied to surfaces that are smooth, dry and complimentary of oils, mold, release agents or other surface contaminants.

The substrate surface should be cleaned to remove whatsoever surface contaminants with an appropriate cleaning method for the customer's substrate, type and quantity of surface contaminants that need to be removed. Annotation: Exist sure to follow all government regulations and the manufacturer's precautions and directions for use when using solvents or other cleaning methods.

After the substrate has been cleaned and dried, the liner is removed from the fastener'south adhesive and without touching the agglutinative, the fastener's adhesive is practical to the surface using low-cal finger pressure level. The fastener can then be rolled downwards, to increment contact of the adhesive with the substrate'due south surface, past one of two methods. Extra care must exist exercised when rolling downwards 3M™ Dual Lock™ Reclosable Fasteners to preclude bending of the stems which can compromise the closure strength. The following methods allow adequate pressure to be practical to the Dual Lock™ without damaging the stems.

The first method uses a manus roller, with the roller bike covered with a Type 170 3M™ Dual Lock™. The 3M™ Dual Lock™ covered roller is rolled over the 3M™ Dual Lock™ applied to the substrate, engaging and disengaging the two 3M™ Dual Lock™ pieces while being rolled down.

The pressure-sensitive adhesive bonds to the substrate on contact and parts tin exist handled immediately. Adhesive bond strength increases with fourth dimension, pressure and temperature. A minimum of one 60 minutes dwell is recommended earlier applying a load or disengaging assembled parts. Recommended time to achieve maximum bond force is 24 hours.

*The technical information is supplied past 3M™ and information should exist considered representative or typical only and should non be used for specification purposes.

Source: https://www.itapestore.com/3m-dual-lock-introduction-buying-guide/

0 Response to "How To Remove 3m Dual Lock Adhesive"

Post a Comment